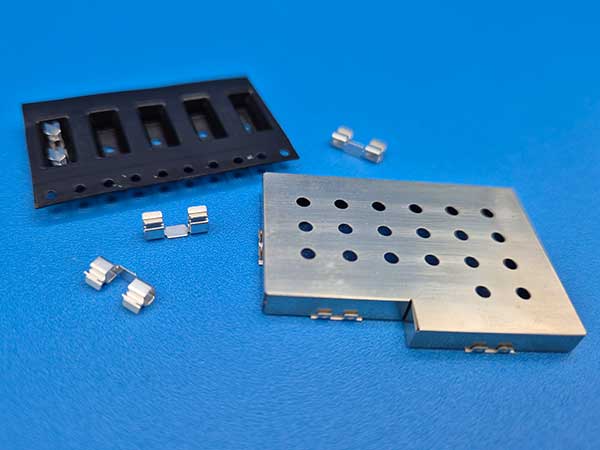

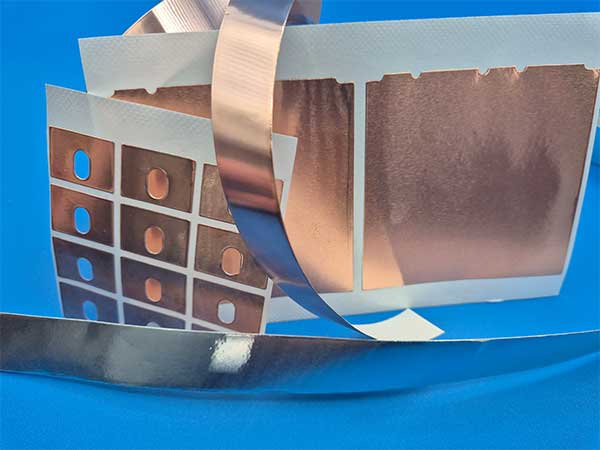

PCB shielding housings provide effective insulation against electromagnetic waves at the board level. Photo etching is the most cost-effective production method for small and medium quantities < to 3000 pieces/year. It allows thanks to its low tooling cost to offer you the industrialized UNIT part, small or very small and medium series, for applications on specifications in a very economical way. After the photo engraving, the pieces are then folded «manually» thanks to folding lines. We have developed our own range of tools to limit your peripheral tooling costs. They are then mounted on a PCB covering one or more components to provide excellent EMIAptitude d'un appareil ou d'un système électrique ou électronique, à fonctionner dans son environnement de façon satisfaisante, sans produire lui-même des perturbations électromagnétiques gênantes pour tout ce qui se trouve dans cet environnement et ne pas être non plus perturbé par les autres équipements électrique ou électronique qui l’entourent. More and RFI shielding. Internal partitions can be added to most designs. Ventilation and access holes can be incorporated into the covers and belts.