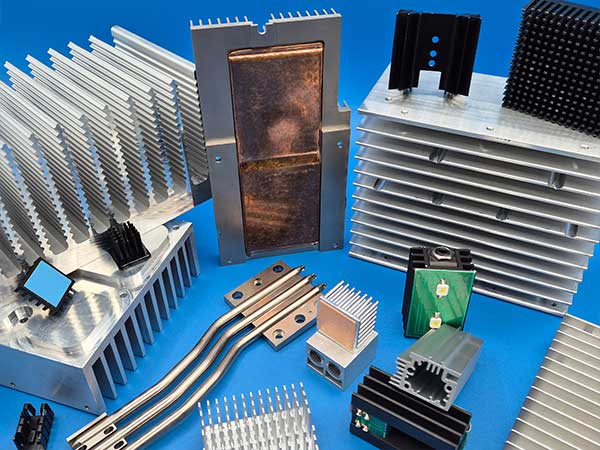

Heat sinks are important! They are the essential components of electronic circuit design. A heat sink is a device intended to dissipate the resulting heat from the Joule effect in a semiconductor element of power electronics. They allow heat to be efficiently removed from electronic devices (notably BJT and MOSFET transistors, Peltier effect and linear regulators) by redirecting it into the ambient air. Their role is to create a larger dissipation surface. Heat transfer to the outside of the device is then facilitated and this reduces the junction temperature of the component. These are devices generally equipped with fins. They should preferably be mounted vertically to facilitate convection cooling. Many types of heat sinks are offered depending on the customer’s application. The power element to be cooled is attached to the cooler with screws or clips. A ‘pad’ made of silicone, a graphite film or even a phase change interface can be inserted if necessary to compensate for the roughness of the different surface states to be contacted. The sizing of your heat sink must be based on thermal Ohm’s law. The latter allows evaluating the temperature rise of the element as a function of the dissipated power.