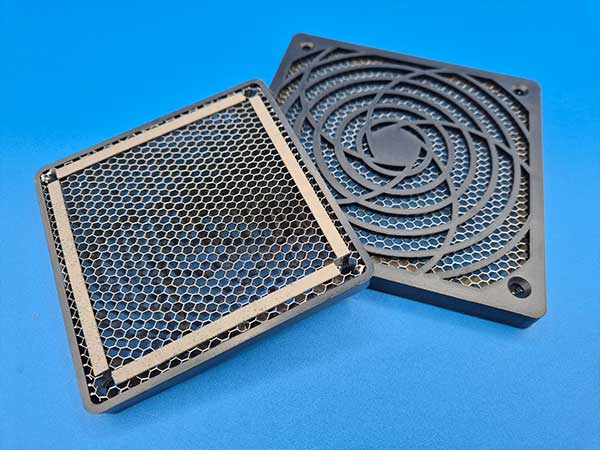

Polyurethanes, thermosetting polymers result from the reaction of the chemical polymerization of an isocyanate with groups carrying a mobile hydrogen (mainly hydroxyl groups). To obtain alveolar materials, this exothermic reaction must be coupled with a gaseous release (chemical or physical). This allows the creation of gas cells in overpressure within the polymer (thus its expansion) as long as the polyurethane is not completely polymerized. The final properties of polyurethane foam depend on the chemical components (DMI isocyanate di phenylmethane), the blowing agent, the process conditions (T°, pressure, humidity) and the nature of the mould facings. Thanks to the constant development of new formulations (new monomers, catalysts and additions of other substances), polyurethanes are today manufactured with a wide variety of textures and hardness. AB2E offers this high quality flame retardant crosslinked filter foam. This product meets Underwriters Laboratories Inc. UL 94 HF-1 self-extinguishing flame safety standards (UL No. provides). It is obtained by a thermal cross-linking process and impregnated in a bath in order to obtain a fire retardation. These filter media designed with calibrated and open cells offer regular filtration. The volume of these foams does not vary in the presence of liquid except with certain solvents. Filter foam also meets European RoHS standard. Our foam offers strong dust resistance and low air resistance. It is generally installed in electronic, computer, telecommunications, medical or industrial equipment. There are many applications: Air filters, ventilation duct… The UL 94 is a standard small-scale vertical flame test. The UL 94 is a small-scale vertical flame test. It is specifically designed to test the flammability of plastic parts used in appliances. It is not intended to reflect the hazards presented by the material we have described under actual fire conditions.