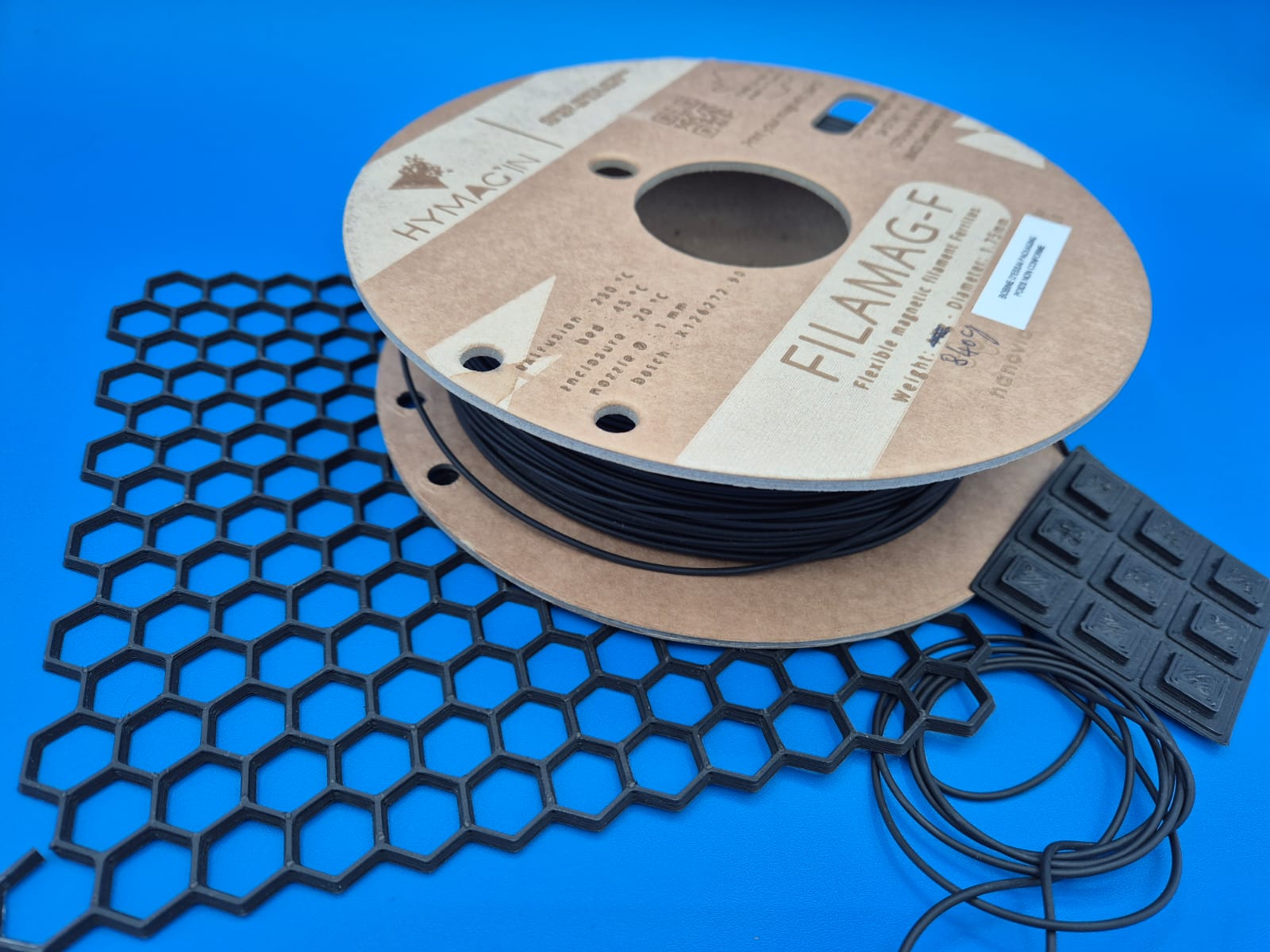

AB2E now offers 3D printing of Hyper-Frequency absorbers to complete its range. In partnership with a French company. It is possible to print various pieces with a standard dimension of 20x20cm and more upon request. This printing can be done by you or ours. The absorbent properties are similar to those we offer in plate. When the absorber material is used in radomes & power supplies, they improve the antenna design by suppressing reflected signals and absorbing surface currents. Microwave absorbers will help reduce unwanted reflective signals in wireless housings. Radio systems combine different frequencies that can interfere in unity. The absorbent materials are then able to suppress crosstalk and separate RF sections in a metal case. As for aerospace applications, they have very specific requirements due to extreme environmental conditions. At high altitude and with the use of specific liquids, great attention must be paid to absorbent materials. Indeed, they can be used indoors or outdoors (elastomeric bases were preferred). Polyurethane materials can be equipped with a specific coating to withstand many fluids that are often specified in the CDC. . Aerospace systems are always equipped with a variety of communication systems and RF probes in a wide frequency range. Our absorbent materials can be tailored to specific operational frequencies, crosstalk between antenna systems is a typical application that requires an absorbent material.