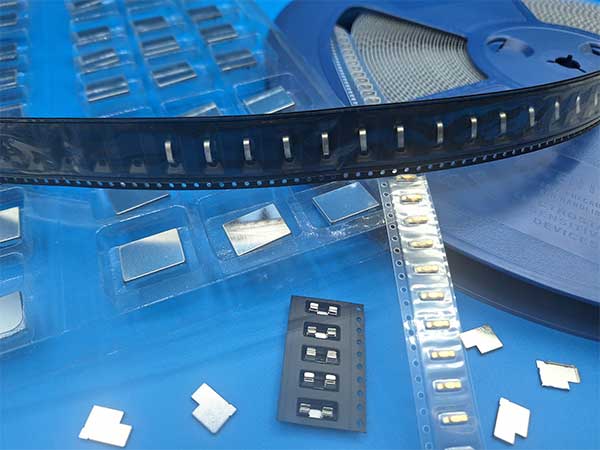

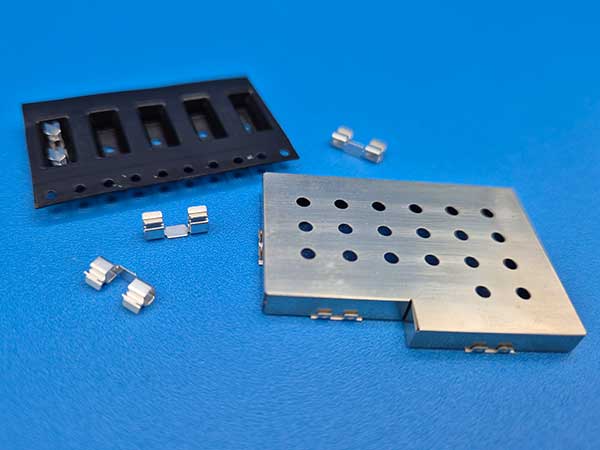

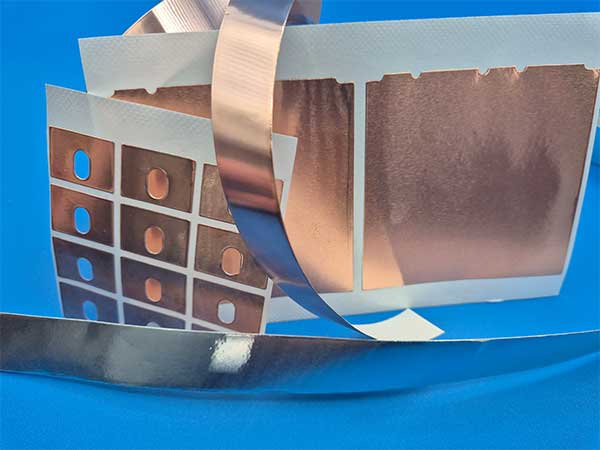

Stamping is generally used for large series > 5000 pieces/year. Stamping and pressing (tools to follow) are very expensive processes. On the other hand, they offer high volume manufacturing capacity with very low unit costs. Typically, a minimum of 100,000 parts are required on a global production to amortize tooling costs. These covers can be made in 1 or 2 parts (belt + lid). They can have fixing legs or not. Different types of lid closures are available. You have the option of compartmentalizing the inside of your shielded enclosure. EMIAptitude d'un appareil ou d'un système électrique ou électronique, à fonctionner dans son environnement de façon satisfaisante, sans produire lui-même des perturbations électromagnétiques gênantes pour tout ce qui se trouve dans cet environnement et ne pas être non plus perturbé par les autres équipements électrique ou électronique qui l’entourent. More covers can be supplied in tape for installation in CMS (reflow) or in tray when they are too large to be spooled.