Thermal Pad / Gap Pad

Our thermal mattresses also called ‘Gap Pad or Gap Filler’ are thermally conductive materials based on silicone or not depending on the desired final application (industry or space). These thermal buffers solve the problems related to heat released by electrical or electronic components. They are almost all electrically insulating except those who have a very high conductivity generally. The “Type” example of use is as follows: connect your electronic component (or heating element) to your heatsink (radiator or chassis). Our mattresses improve the heat exchange between these 2 parts. The natural self-adhesion is appropriate for easy pre-assembly. You should know that air is a very bad thermal conductor. Our mattress fills these empty spaces. These spaces can be related to different factors. The latter are empty spaces caused by: component tolerances, different stack heights or different expansion coefficients. The mattress then manages the heat transfer flow in a + or – fast way according to the need. We can size them with you to optimize this dissipation. Non-elastic plastic mattresses allow for thermal contact on large surfaces with tolerances at near-zero pressure. In addition to their thermal quality, all our mattresses have very good anti-vibration damping characteristics. This allows you to compensate for your surface irregularities.

Thermal Films & Foil

Our thermally conductive and electrically insulating interfaces, also called ‘Sil Pad’, are made from silicone elastomers or not. Our thermal films compensate for surface irregularities (flatness) on components that require heat dissipation. They offer many advantages compared to thermal greases. There is less loss of material volume. Indeed, the quantity of material is perfectly controlled and is therefore in line with the real need. It has no possible air bubbles during the setup. Unlike greases, storage can be long if the film has no adhesive of course. A film provided with an adhesive will not be able to converse for more than 1 year. These interfaces are more efficient than mica or ceramics. We also have in this range a double-sided adhesive product with very resistant structural bonding. On the other hand, we advise against this TAT because the thermal performances are very reduced. Indeed, as current electronic components diffuse more and more energy, adhesives are not recommended. We also offer other particular materials without silicone. These materials are to be reserved for aeronautical or space applications because their cost is significant. They have very good thermal performance and do not bleed. They are particularly appreciated for all ’empty’ applications.

Graphite Foils

Graphite is one of the allotropes of carbon. In other words, it is one of the crystalline forms of the simple body that corresponds to the chemical element carbon. The diamond, for example, is another. The appearance of graphite is that of a black solid with a sub-metallic sheen; its hardness is low, between 1 and 2 on the Mohs scale. It is the particular structure of graphite that makes it electrically conductive. Graphite has a wide variety of properties and uses. This mineral is sought for its electrical and thermal conductivity. The properties of graphite are: its tenderness, chemical inertness, heat resistance, and lubricating power. Our graphite films also called ‘Graphite Foil’, as you will have understood, are therefore not electrically insulating. The anisotropy of its thermal properties, linked to a weight gain (up to 30%) makes them interesting for the fields of application of “Heat-Spreader”. So, for all applications of very high power. We also have pure “pyrolytic” Graphite. They are perfectly suited as an economical alternative for conventional radiator systems. Their range of use, which can reach up to +500°C, make them very interesting components for applications in very hot areas. In addition, vacuum applications are also possible.

Thermally conductive greases

Thermal grease (or thermal paste) plays a crucial role in the performance of electronic devices. This often underestimated substance is essential for heat transfer between internal components. There are several types of thermal greases. Each has unique properties. This composition allows it to fill the microscopic surface imperfections. The performance of a thermal grease is measured and expressed in watts per meter-kelvin (W/m*K). The application of thermal grease is a very delicate step. Excessive quantity can hinder thermal conduction. While an insufficient quantity can create hot spots on the CPU. A common method is to apply a small amount to the center of the CPU and use either a spatula or card (type CC) to spread the paste evenly over the entire surface. Some will prefer the ‘pea’ or ‘line’ method, where a small amount is deposited in the center without additional display, leaving the heat sink to press and spread the paste during its installation. Major drawback of thermal grease, over time it can dry out or degrade, reducing its effectiveness. It is advisable to replace it every 2 to 5 years. The sign indicating the need for replacement is an increase in the T° of your equipment. In applications mechanically exposed to shocks and vibrations? greases are not recommended. They are particularly suitable for stationary applications. Laptops, PCs, graphics cards, CPU coolers… Thermal grease containing metal compounds, can be harmful to the environment. It is therefore important not to throw it in ordinary household waste

Phase Change Material

Ces matériaux de gestion thermique permettent de gagner du temps et de l’argent sans transiger sur les performances thermiques. Ils sont appelés aussi « Change Thermal Phase » ou « Hi-Flow ». Ils sont des excellents substituts à la graisse. Ils sont placés généralement entre des CPU, micro-processeurs et des dissipateurs de chaleur « Heat-Sink ». Ces thixotropes sont faciles à utiliser. Ils ne coulent pas pendant les températures de fonctionnement des équipements. A température ambiante, ils sont solides et faciles à manipuler. En effet, ils ont la propriété de passer d’un état solide à un état dit « visqueux » à des températures prédéfinies. Ils permettent d’assurer la totale imprégnation de l’interface sans débordement à l’extérieur. Ils permettent de combler les interstices lorsqu’il change « de phase » (leur T° de fusion). Les performances thermiques du dissipateur utilisé sont ainsi pleinement optimisées. A température ambiante, ces interfaces à changement de phase ne sont pas collants. Par contre ils ne se déclinent pas avec un adhésif de positionnement. Les avantages sont nombreux : une interface thermique comparable à de la graisse, mais sans saleté, sans dégâts et sans difficulté.

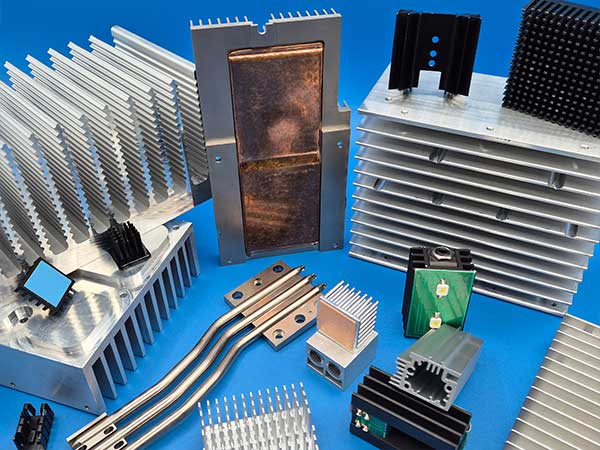

Heats Sinks

Heat sinks are important! They are the essential components of electronic circuit design. A heat sink is a device intended to dissipate the resulting heat from the Joule effect in a semiconductor element of power electronics. They allow heat to be efficiently removed from electronic devices (notably BJT and MOSFET transistors, Peltier effect and linear regulators) by redirecting it into the ambient air. Their role is to create a larger dissipation surface. Heat transfer to the outside of the device is then facilitated and this reduces the junction temperature of the component. These are devices generally equipped with fins. They should preferably be mounted vertically to facilitate convection cooling. Many types of heat sinks are offered depending on the customer’s application. The power element to be cooled is attached to the cooler with screws or clips. A ‘pad’ made of silicone, a graphite film or even a phase change interface can be inserted if necessary to compensate for the roughness of the different surface states to be contacted. The sizing of your heat sink must be based on thermal Ohm’s law. The latter allows evaluating the temperature rise of the element as a function of the dissipated power.