EMC Driver Gasket EMISEAL

EMI/SEAL are seals for all applications of enclosures, enclosures, hatches, indoor… or a purely EMC gasket is required. These gaskets are made by knitting a strand of metal knitting yarn (monel, tinned steel, etc.) around an elastomeric core (cellular neoprene, silicone, urethane foam, etc.). They have good resilience and excellent shielding attenuation. Their design makes them resistant to the environment over time. Monel is very often used in the HF, UHF and VHF frequency range. Tinned copper steel is more suitable for it in magnetic field. The judicious choice of the nature of the knitting yarns allows to have a good galvanic compatibility and avoids corrosion with the surfaces to be coupled. These seals can also be used for EMI (electromagnetic pulse) protection.

Conductive EMC foam on all 3 axes

3-axis conductive foam is a urethane based foam combined with Mesh. It has a low density. It is completely coated with a copper + nickel mixture, which gives it a low resistance electrical conductivity on the three axes: X, Y and Z. It is therefore conductive (horizontally and vertically) which ensures a particularly good connection between the top and bottom of the elements to be put in electrical continuity. This allows it to deliver excellent EMI shielding performance when used as a conductive EMI seal. It is very economical since there is no need for groove machining. The material is available as a sheet or roll up to 1000 mm wide or as a die cut seal according to customer plan. Conductive adhesive is available as an option. This material will provide good dust tightness.

Solderable PCB EMI Seal – SMGS Type W

SMGS type W contact pads are used exclusively on printed circuit boards (PCBs) and are an excellent alternative to metal SMD contacts. They have good electrical and physical properties. These contact springs have high adhesion thanks to the SMT (TMS) process. They have excellent temperature resistance as well as excellent spring and ground connection properties. They also have high abrasion resistance. The conductive coating that surrounds these studs is copper with tin plating to facilitate the soldering and reflow soldering process.

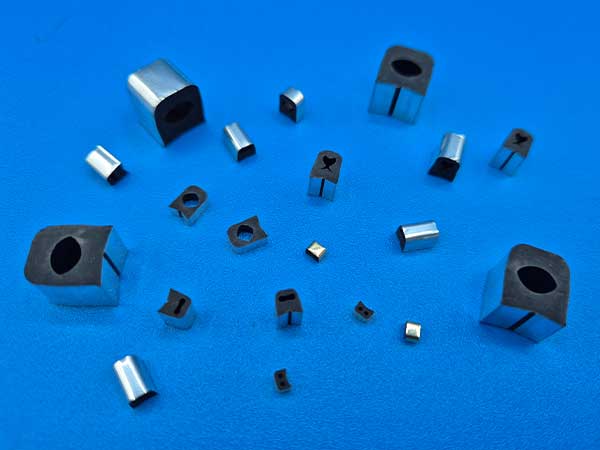

Contact SMD for PCB gold plated

AB2E offers a wide range with more than 120 standard parts ranging from 1.3 mm to 13 mm in height. These contacts are in Cu Be material gilded with fine gold in standard declination. The process of use is simple by the reflow welding method. The choice of Cu Be is due to the fact that it is easy to work. It is also resistant to corrosion and abrasion (treatment with its gold flash). It is elastic. This type of product is almost indestructible. It can withstand sharp temperature fluctuations without affecting its operation. For other shapes, customer plan from your dxf or step files. It can be used «as a so-called classic EMC gasket» by positioning these contacts close to each other to form an almost continuous cord.

EMC contact fingers in CuBe

Beryllium copper (CuBe) contact bands are made from beryllium copper alloy. The sheets are cut by punching or engraving, then stamped to be shaped. Heat treatment then ensures “shape memory” and increased mechanical elasticity. They can receive various treatments to increase their conductivity or to improve galvanic couples. The existing shapes give a very low remanence spring effect and gives excellent EMI/RFI electromagnetic protection. They are also used for different forms of mass…. ideally suited for shielding applications requiring frequent cycles of opening/closing operations, such as shielded enclosure doors.

EMC Foam Fabric Gasket (FOF)

These standard seals are made in Asia. They have a core of Polyurethane foam covered with a conductive fabric of Nickel-plated Copper. They are specially designed for all EMC In-Door applications. They are used mainly at the level of cabinet closures, cabinets, hatches, doors… They have great flexibility with regard to the closing system and the chassis over long lengths. The excellent high frequency shielding efficiency as well as the adhesive make them easy to use seals (no grooving machining). They can be used on thin metals because of their extreme flexibility. These seals are a good way to reduce shielding costs. Our catalogue offers a very wide range of standard sizes and shapes.