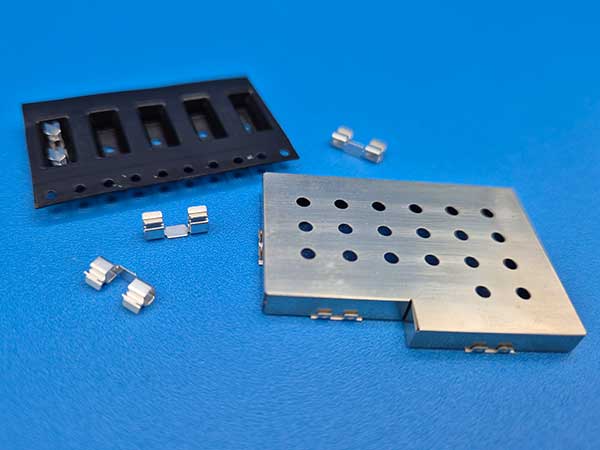

Clips SMT/ TMS – Mounting Shielding Boxes

The clip is made of tinned steel. The clips are delivered in CMS spool. They are therefore easily implanted on the PCB in TMS technology. Then, we simply clip the monobloc cover. We have an RF shield cover in 2 parts (clip=belt + cover). This results in a very significant economic gain compared to stamping. The second advantage is the reduction of the height compared to a «classic» 2-part stamped cover.

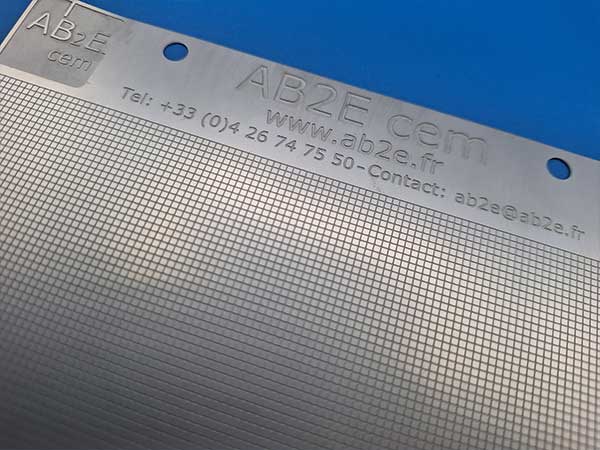

Easyshield EMC plates Prototype

AB2E has designed and developed this innovative new shielding product. It allows the R&D department to manufacture their own shielding box(s) for electromagnetic compatibility testing. Reproducibility is very easy because it is this same material that will be used in series by us. The cover can be made in 1 or 2 parts. It can have cavities or not. It is possible to integrate interior partitions, mounting brackets… This type of manufacturing has a very low cost and this in an ultra short time (plates in permanent stock at AB2E). We have equipped some of the best-known accredited testing laboratories. These products are widely used in Wifi, RF/HF, Wireless, and more generally in all Radio and home automation products.

EMC Shielding Covers in Chemical Cutting

PCB shielding housings provide effective insulation against electromagnetic waves at the board level. Photo etching is the most cost-effective production method for small and medium quantities < to 3000 pieces/year. It allows thanks to its low tooling cost to offer you the industrialized UNIT part, small or very small and medium series, for applications on specifications in a very economical way. After the photo engraving, the pieces are then folded «manually» thanks to folding lines. We have developed our own range of tools to limit your peripheral tooling costs. They are then mounted on a PCB covering one or more components to provide excellent EMI and RFI shielding. Internal partitions can be added to most designs. Ventilation and access holes can be incorporated into the covers and belts.

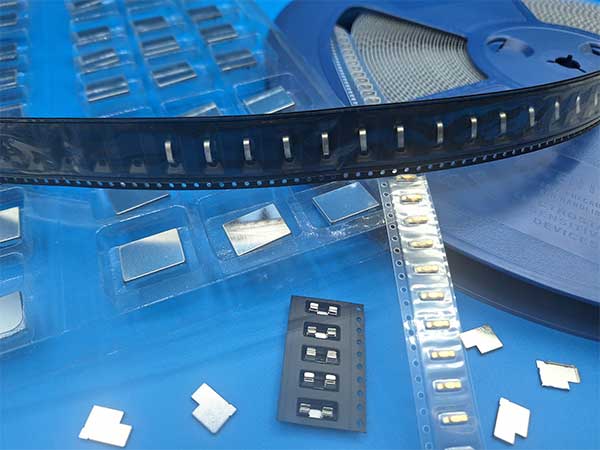

EMC Stamped Shield Covers

Stamping is generally used for large series > 5000 pieces/year. Stamping and pressing (tools to follow) are very expensive processes. On the other hand, they offer high volume manufacturing capacity with very low unit costs. Typically, a minimum of 100,000 parts are required on a global production to amortize tooling costs. These covers can be made in 1 or 2 parts (belt + lid). They can have fixing legs or not. Different types of lid closures are available. You have the option of compartmentalizing the inside of your shielded enclosure. EMI covers can be supplied in tape for installation in CMS (reflow) or in tray when they are too large to be spooled.